- Whatsapp: 8613738300923

- Email: [email protected]

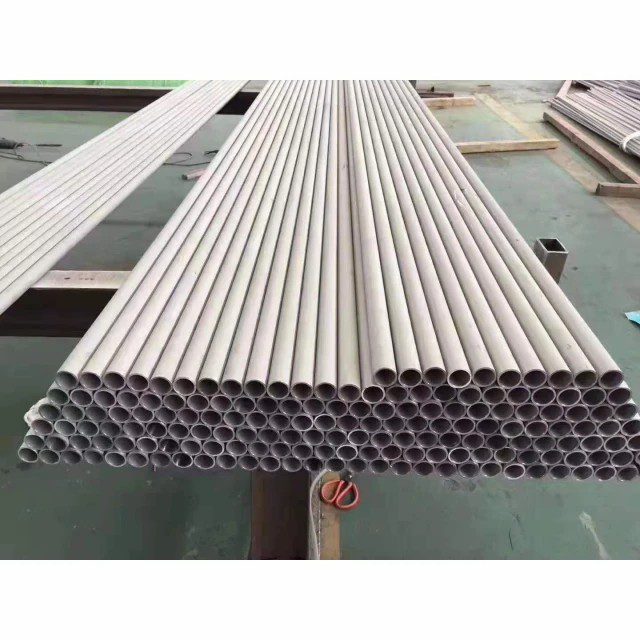

Home / products / Stainless Steel Pipe / Stainless steel heat exchanger tube

Our main material of stainless steel seamless pipe

Austenitic stainless steel :

TP304, TP304L, TP304H, TP316, TP316H, TP316Ti, TP316L, TP321, TP321H, TP347H, TP347HFG, 904L, TP310H, TP310S,

TP304/304L, TP316/316L , TP317, TP317L, TP316LMo≥2.5; etc

Duplex steel steel、 super duplex steel :

S31803; S32205; S31500; S32750;

Our main material of stainless steel seamless pipe

Austenitic stainless steel :

TP304, TP304L, TP304H, TP316, TP316H, TP316Ti, TP316L, TP321, TP321H, TP347H, TP347HFG, 904L, TP310H, TP310S,

TP304/304L, TP316/316L , TP317, TP317L, TP316LMo≥2.5; etc

Duplex steel steel、 super duplex steel :

S31803; S32205; S31500; S32750;

The demensions we can manufacture are below

| Norminal Pipe Size | Outside Diameter | Norminal Wall Thickness | |||||||||||||||||

| DN | inch | D | SCH5s | SCH10s | SCH10 | SCH20 | SHC30 | SCH40s | STD | SCH40 | SCH60 | SCH80s | XS | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | XXS |

| 6 | 1/8 | 10.3 | — | 1.24 | — | — | — | 1.73 | 1.73 | 1.73 | — | 2.41 | 2.41 | 2.41 | — | — | — | — | — |

| 8 | 1/4 | 13.7 | — | 1.65 | — | — | — | 2.24 | 2.24 | 2.24 | — | 3.02 | 3.02 | 3.02 | — | — | — | — | — |

| 10 | 3/8 | 17.1 | — | 1.65 | — | — | — | 2.31 | 2.31 | 2.31 | — | 3.2 | 3.2 | 3.2 | — | — | — | — | — |

| 15 | 1/2 | 21.3 | 1.65 | 2.11 | — | — | — | 2.77 | 2.77 | 2.77 | — | 3.73 | 3.73 | 3.73 | — | — | — | 4.78 | 7.47 |

| 20 | 3/4 | 26.7 | 1.65 | 2.11 | — | — | — | 2.87 | 2.87 | 2.87 | — | 3.91 | 3.91 | 3.91 | — | — | — | 5.56 | 7.82 |

| 25 | 1 | 33.4 | 1.65 | 2.77 | — | — | — | 3.38 | 3.38 | 3.38 | — | 4.55 | 4.55 | 4.55 | — | — | — | 6.35 | 9.09 |

| 32 | 1 1/4 | 42.2 | 1.65 | 2.77 | — | — | — | 3.56 | 3.56 | 3.56 | — | 4.85 | 4.85 | 4.85 | — | — | — | 6.35 | 9.7 |

| 40 | 1 1/2 | 48.3 | 1.65 | 2.77 | — | — | — | 3.68 | 3.68 | 3.68 | — | 5.08 | 5.08 | 5.08 | — | — | — | 7.14 | 10.15 |

| 50 | 2 | 60.3 | 1.65 | 2.77 | — | — | — | 3.91 | 3.91 | 3.91 | — | 5.54 | 5.54 | 5.54 | — | — | — | 8.74 | 11.07 |

| 65 | 2 1/2 | 73 | 2.11 | 3.05 | — | — | — | 5.16 | 5.16 | 5.16 | — | 7.01 | 7.01 | 7.01 | — | — | — | 9.53 | 14.02 |

| 80 | 3 | 88.9 | 2.11 | 3.05 | — | — | — | 5.49 | 5.49 | 5.49 | — | 7.62 | 7.62 | 7.62 | — | — | — | 11.13 | 15.24 |

| 90 | 3 1/2 | 101.6 | 2.11 | 3.05 | — | — | — | 5.74 | 5.74 | 5.74 | — | 8.08 | 8.08 | 8.08 | — | — | — | — | — |

| 100 | 4 | 114.3 | 2.11 | 3.05 | — | — | — | 6.02 | 6.02 | 6.02 | — | 8.56 | 8.56 | 8.56 | — | 11.13 | — | 13.49 | 17.12 |

| 125 | 5 | 141.3 | 2.77 | 3.4 | — | — | — | 6.55 | 6.55 | 6.55 | — | 9.53 | 9.53 | 9.53 | — | 12.7 | — | 15.88 | 19.05 |

| 150 | 6 | 168.3 | 2.77 | 3.4 | — | — | — | 7.11 | 7.11 | 7.11 | — | 10.97 | 10.97 | 10.97 | — | 14.27 | — | 18.26 | 21.95 |

| 200 | 8 | 219.1 | 2.77 | 3.76 | — | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 10 | 273.1 | 3.4 | 4.19 | — | 6.35 | 7.8 | 9.27 | 9.27 | 9.27 | 12.7 | 12.7 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 300 | 12 | 323.9 | 3.96 | 4.57 | — | 6.35 | 8.38 | 9.53 | 9.53 | 10.31 | 14.27 | 12.7 | 12.7 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 350 | 14 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | — | 9.53 | 11.13 | 15.09 | — | 12.7 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | — |

| 400 | 16 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | — | 9.53 | 12.7 | 16.66 | — | 12.7 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | — |

| 450 | 18 | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | — | 9.53 | 14.27 | 19.05 | — | 12.7 | 23.83 | 29.36 | 34.96 | 39.67 | 45.24 | — |

| 500 | 20 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | — | 9.53 | 15.09 | 20.62 | — | 12.7 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | — |

Technological process

Production standards

| NO. | Standard type | Production standard |

| 1 | European standard | EN10216-5; EN10216-2 |

| 2 | German standard | DIN 17456; DIN 17458 |

| 3 | American Standard | ASTM A312; A213; A269; A511; A789; A790; |

| ASME SA213; SA312; SA789; SA790; | ||

| ASTM B423, ASTM B407, ASTM B668, ASTM B163; | ||

| ASME SB163, ASME SB423,ASME SB407,ASME SB668; | ||

| 4 | Japanese standard | JIS G3459; G3463 |

| 5 | Russian standard | GOST 9941;GOST 5632 |

| 6 | National standard | GB/T14975, GB/T14976; GB13296; GB5310; GB9948 |

Email:

[email protected]Phone:

8613738300923Location:

2nd Floor, No. 261, Xiayang Street, efang Street, Yongxing Street, Longwan District, Wenzhou City

Privacy Policy | SiteMap

Copyright GENCEL STAINLESS STEEL CO.,LIMITED